RAS offers innovative, time tested and proven solutions for sheet metal forming backed by an experienced team of application engineers to ensure you have the right machine for your application. Service and support are provided by RAS Systems, LLC located in Peachtree City, GA.

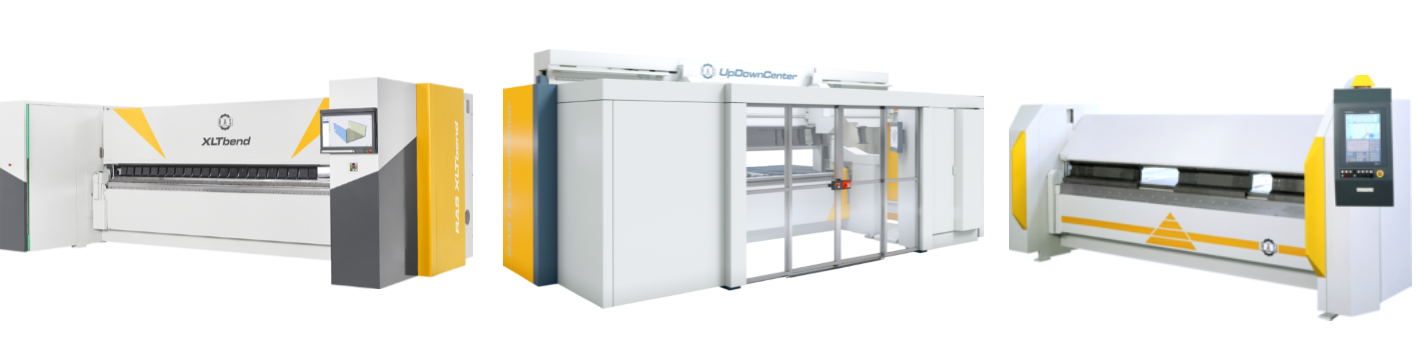

XLTbend

For those who want to form complex precision sheet metal parts like cassettes, panels, and boxes profitability even in small batches, the XLTbend is a perfect fit.

FLEXIbend

The FLEXIbend metal folding system is a study in flexibility. There are almost no limitations to your imagination, when you want to create unique, complex parts with a high level of added value. .

TURBObend

Designed for roof and wall profiles

For many roofers and metal builders the TURBObend is the most advanced, easy to use and most accurate folding machine in the world.

Up-Down Center

Semi automated panel bender

The UpDownCenter-2 is a semi-automatic bending center for panels and boxes up to 4060 mm bending length and up to 400 mm box height. With up to 4 mm bending capacity, it is ideal for thin and medium material thicknesses.

RAS XLT One Click Programming Software

Benefits of Folding

During the folding sequence the blank rests on the sheet support table. A gauging system positions the part to the bend line. The upper and lower beam clamp the blank. During the bending cycle the folding beam moves up around a pivot point. On up-down acting machines, the folding beam moves upwards or downwards, depending on the bending direction.

The part rests on the table (no fatigue, short cycle times)

The gauging system positions the part to the bend line (operator training finished in no-time)

Upright posture, easy operation (no health problems)

Usually one operator is sufficient even for large, cumbersome and heavy parts (low labor/parts costs

Create a part program automatically.

Import a STEP, DXF or GEO file with the part geometry.

The software analyzes the STEP file and automatically generates a 3D model. For DXF files, the programmer has to add to the bend angle.

Overbend angles for springback compensation are added from material tables.